MusicBox

Intro

A MusicBox is an automatic musical instrument in a box that produces musical notes by using a set of pins placed on a revolving cylinder to pluck the tuned teeth of a steel comb. Usually the song which is played on a commercial MusicBox is static. The idea of our solution is to made MusicBox more dynamic, so the end-user can customize pin placement and play more songs.

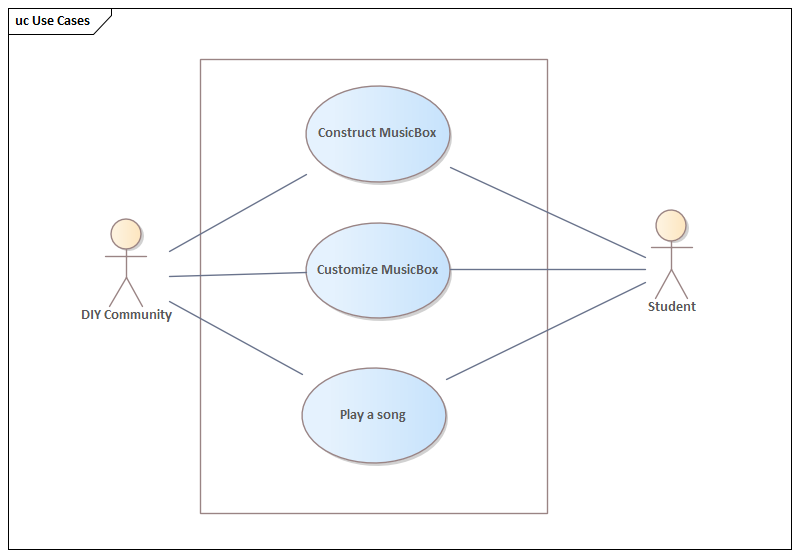

UC

The image below illustrates main defined use cases and end-users of our solution. Our goul is not to sell the product but rather show the alternative way to construct such thing and contribute to the DIY(Do it yourself) community.

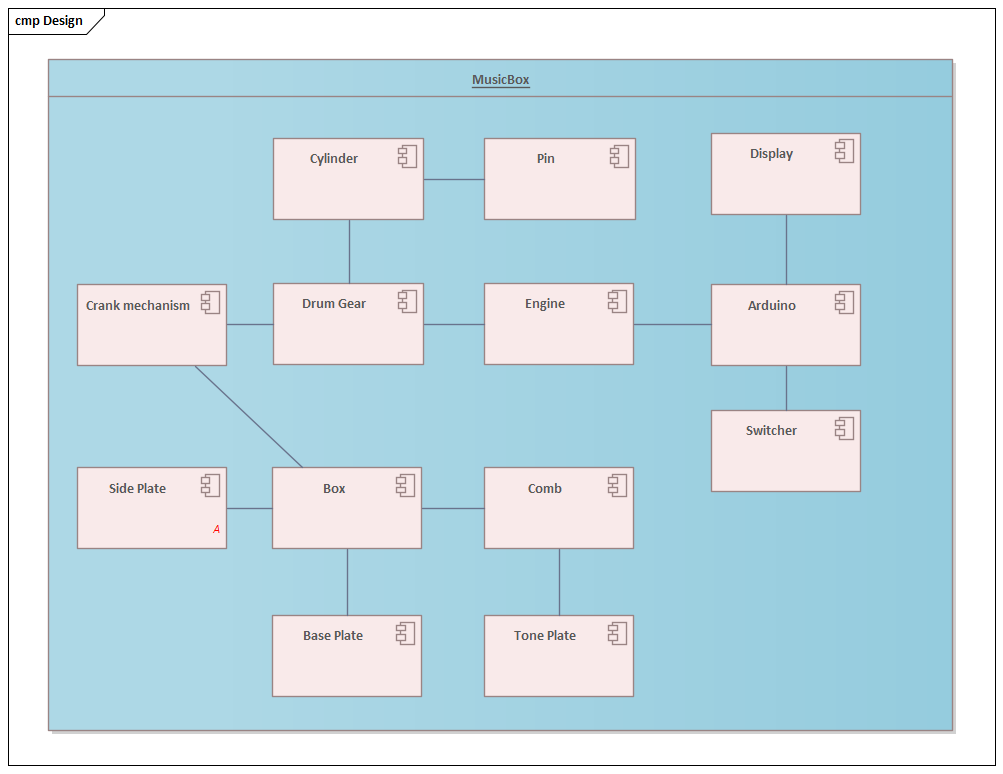

Design

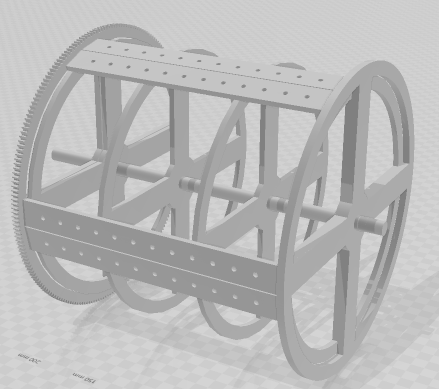

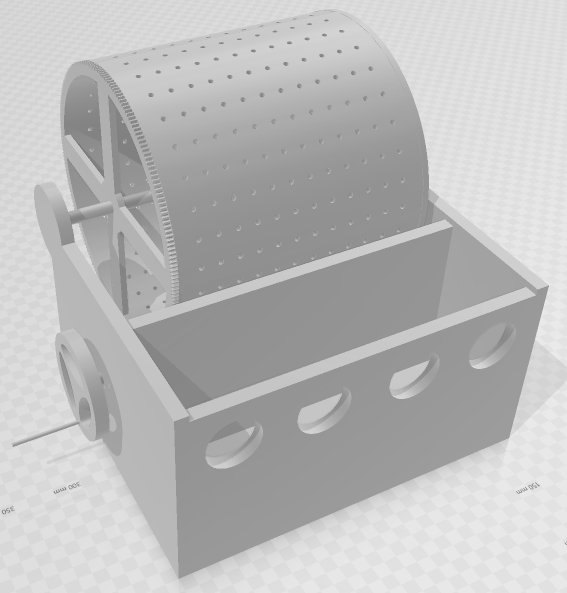

Our proposet design consists of the components that are shown on the image below.

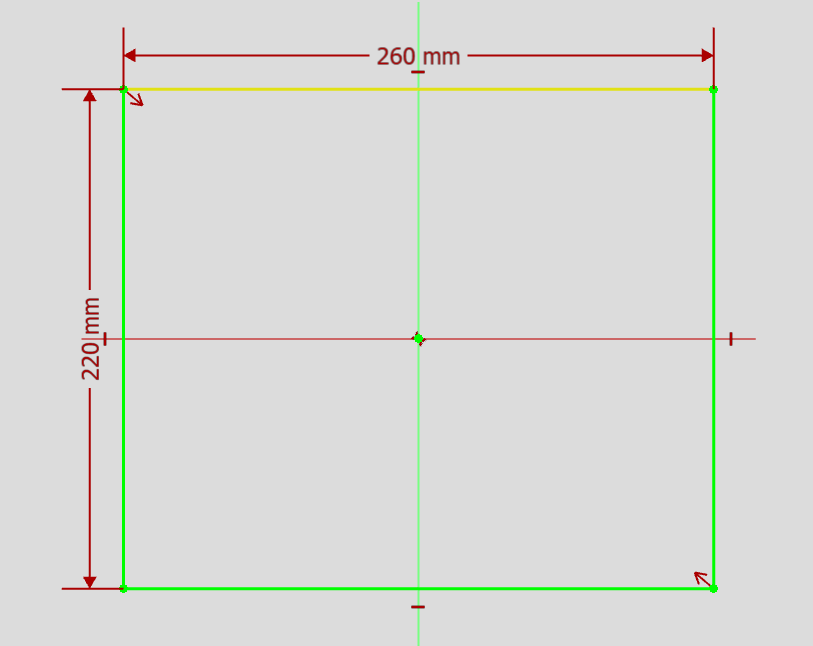

Box

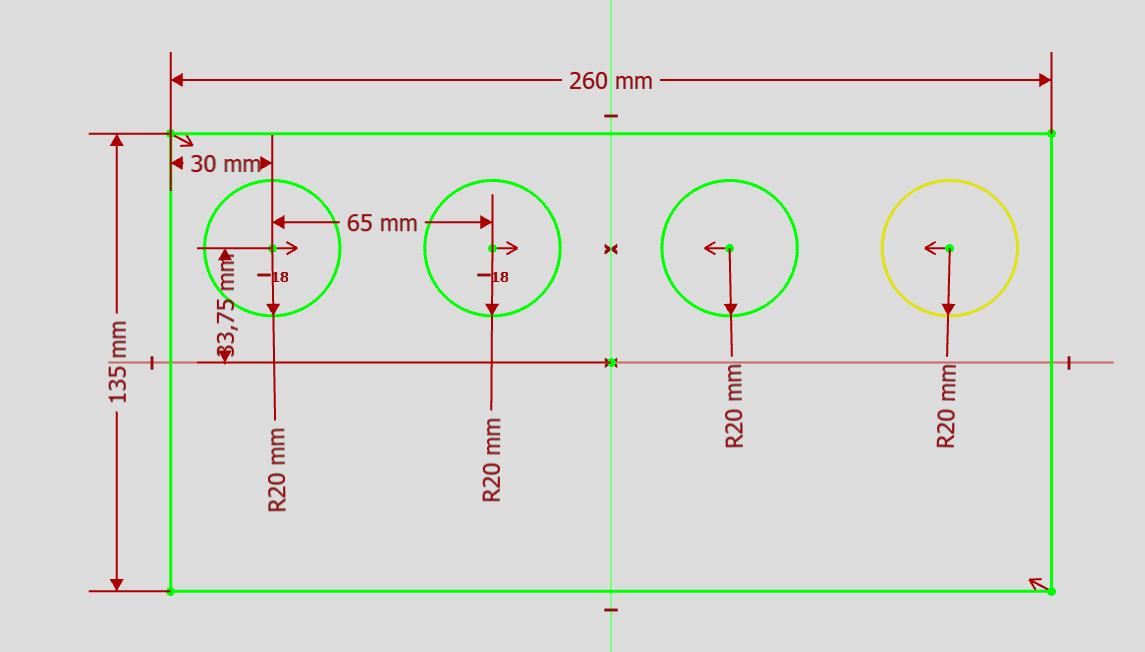

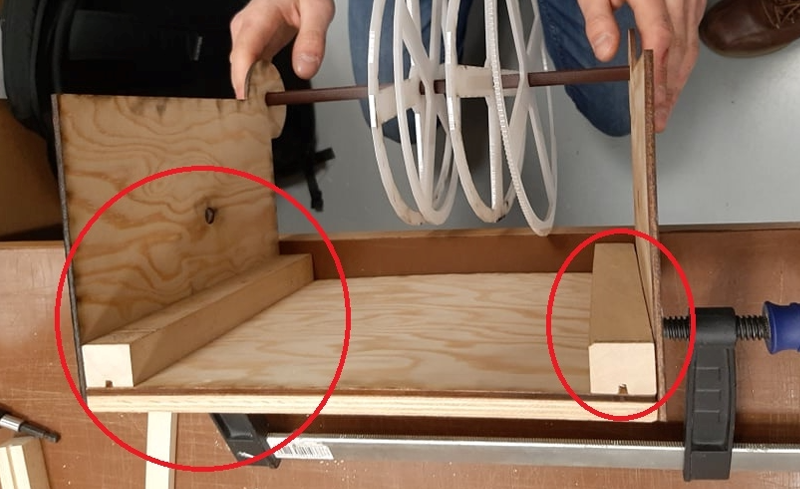

A case is constructed by five wooden plywood plates (base plate, two side plates, middle plate and front plate) joined together with construction wood screws.

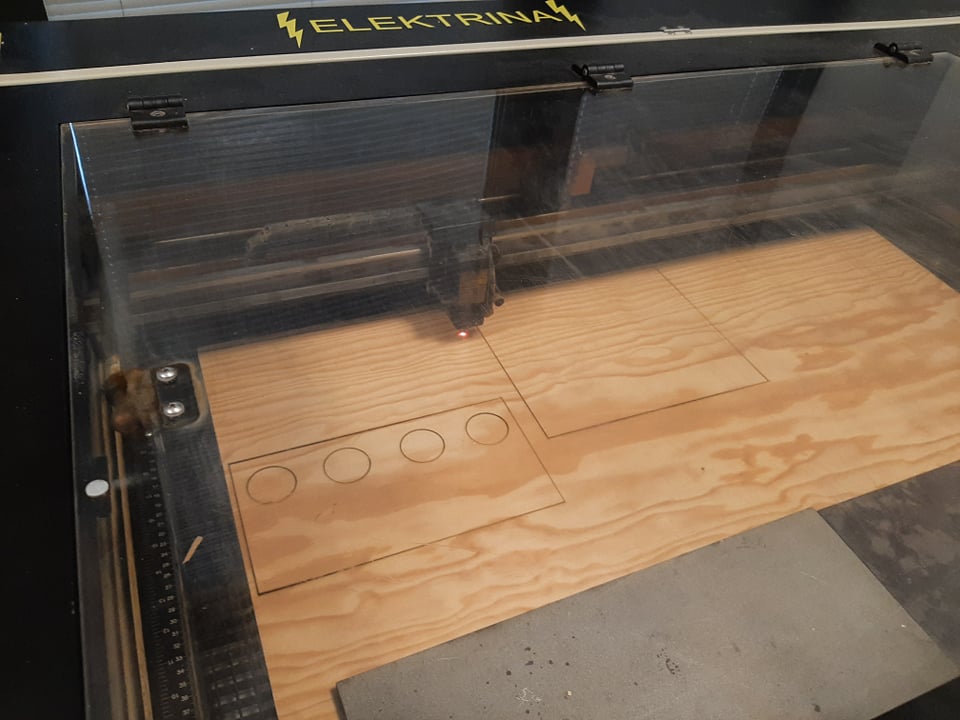

Final parts were cut off from the plywood using laser cutter.

The original design did not expect that the final parts would be that thin, so we had to add support parts for the screws.

Comb

Comb is composed of two main parts:

- 5mm thick metal base plate with carved slots

- Metal plates that are placed into the slot (tuned to play specific tone)

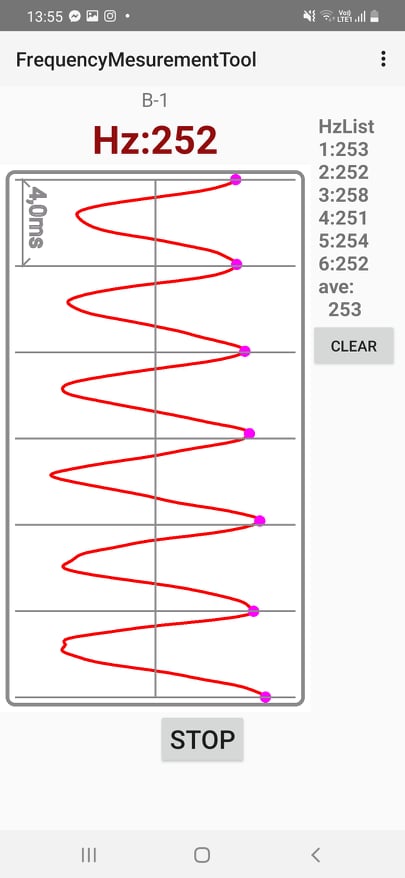

The main plate was constructed in the Craft room using angle grinder, disk grinder and files.The producing of harmonic plates consists of cutting off small parts of material from the edges in order to achieve resonance frequencies of desired tones.

For the validation of final tone resonance we used mobile application for measuring sound signal frequencies.

Final comb is able to play 12 notes starting from C4 to B5 (2 octaves).

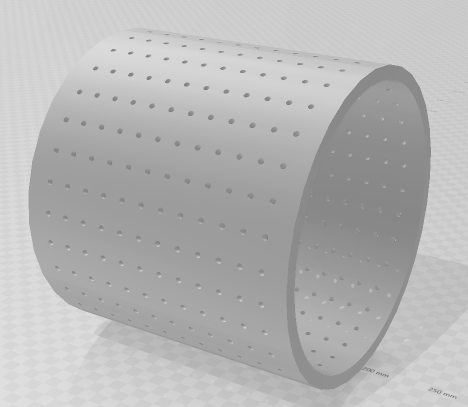

Cylinder

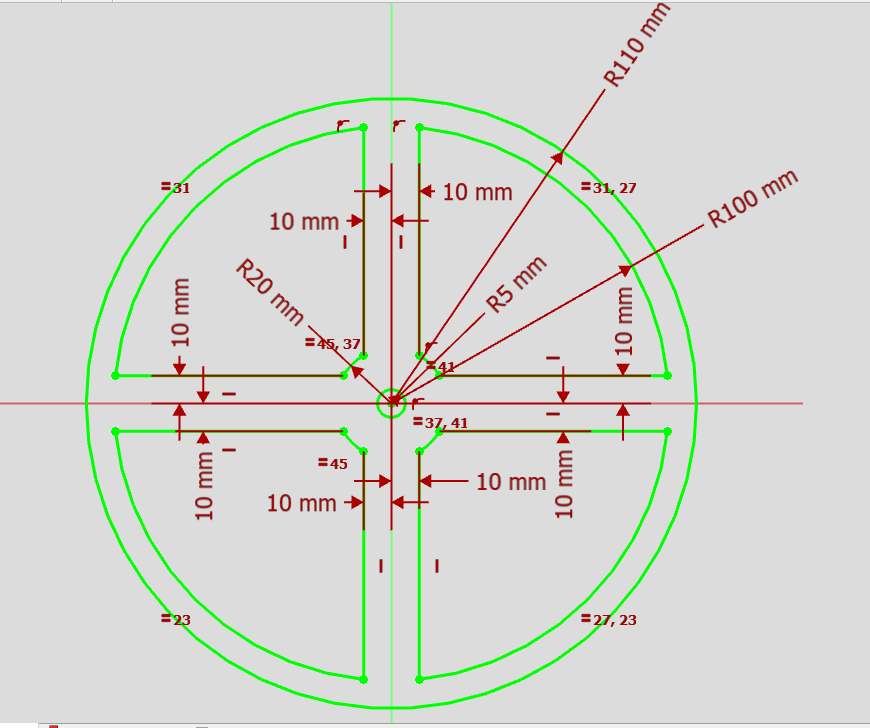

First parameter which was considered when designing cylinder was the number of notes that could be played. We decided to include 32 plates containing holes for pins that could play 12 possible notes at the same time.

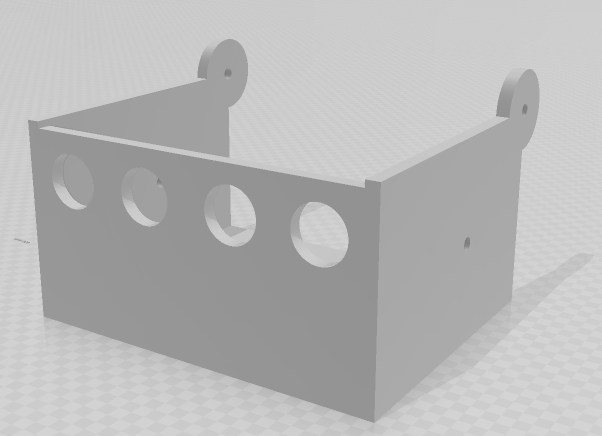

We were not able to print the original design because the dimensions of object were too large for the 3D printer we used:

- lenght: 200 mm

- radius: 110mm

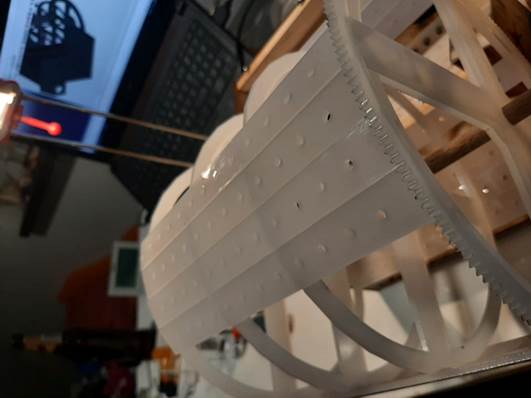

We had to redesign this part. Instead of creating one solid part we decided to split it into individual plates. We also added the support wheels on which the plates sit.

Motion of the cylinder is driven by gear wheel located on the left side.

Material used for cylinder construstion is acrylic plexiglass. Cylinder body is filled by joining 32 parts cut out by laser joined with glue.

Pins

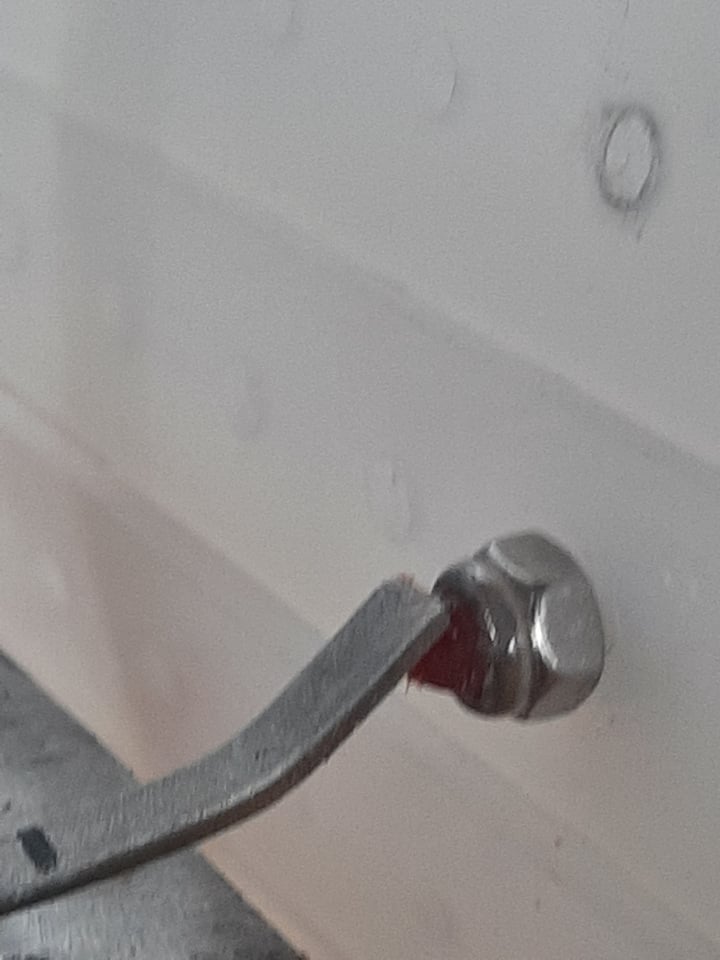

While experimenting with the comb we noticed that the best tone was achieved by hitting the metal plate with the same material (...metal :) ). So the idea was to use metal screws as playing pins placed onto the cylinder.

Upon final assembly we noticed that the tone was not sufficient so we experimented with different pin designes.

Best result was achieved by using metal screw which head was ground into triangular shape.

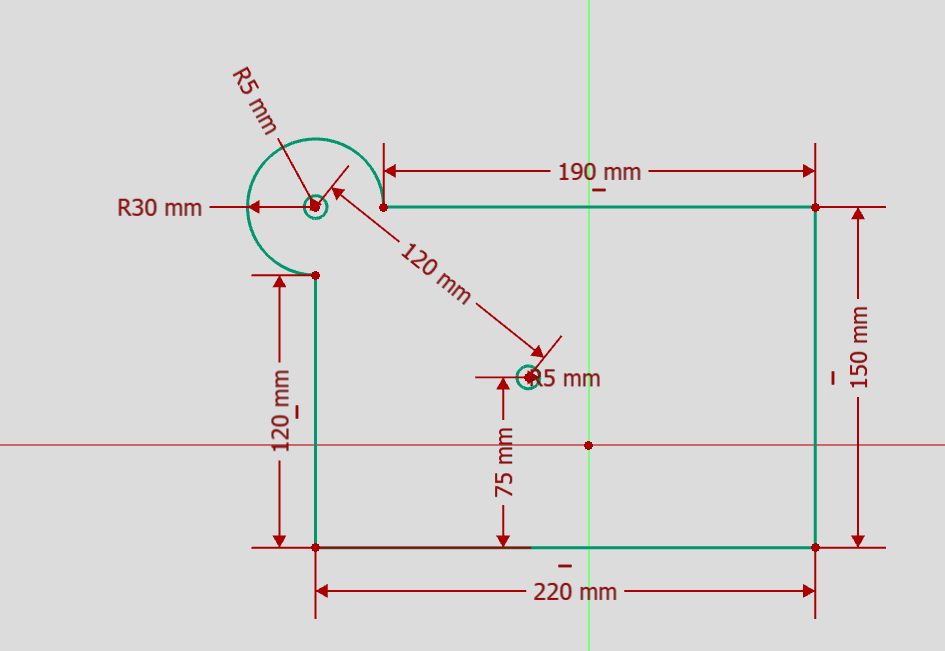

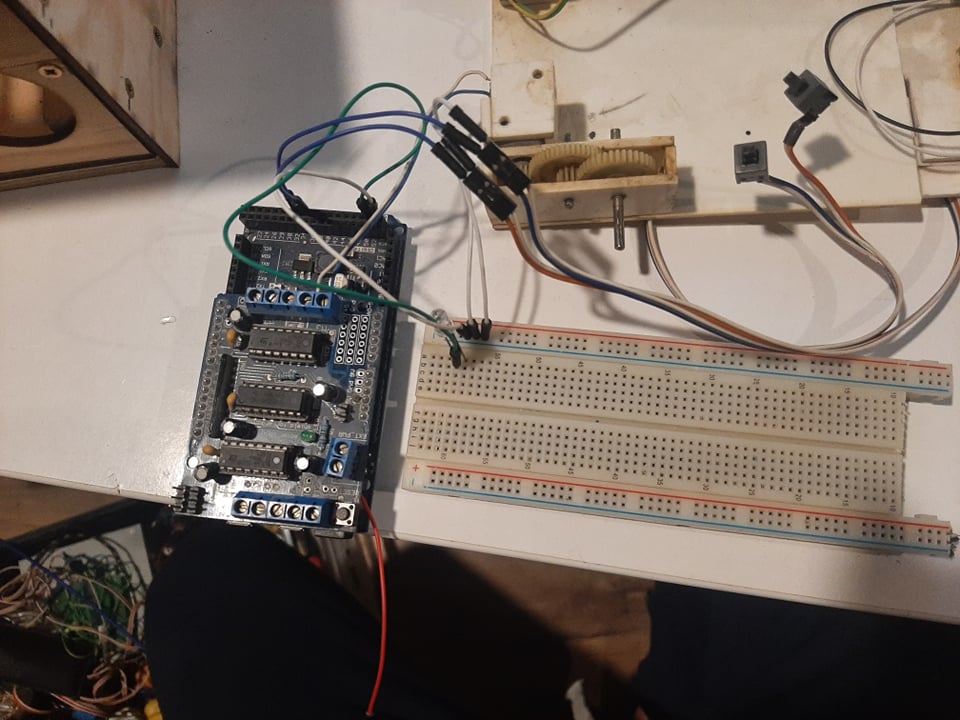

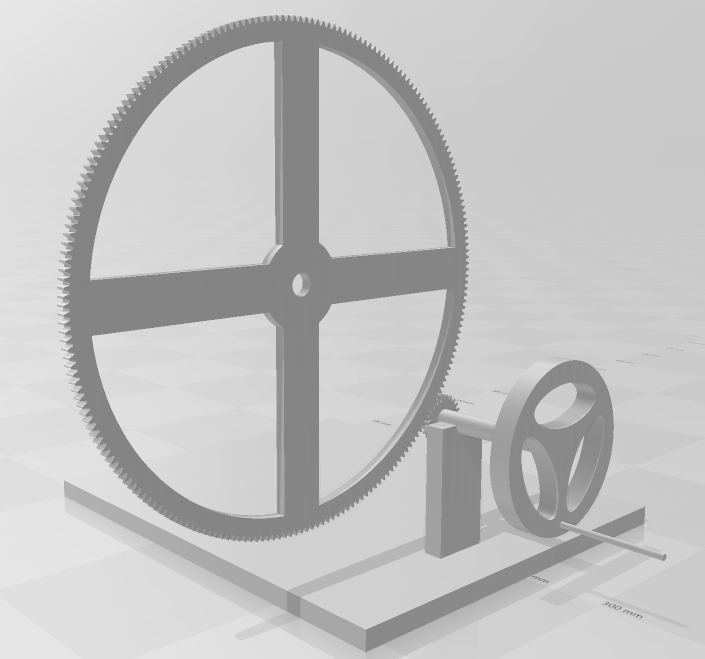

Crank mechanism

In the original design we planned to drive the cylinder by DC motor (link) controlled by Arduino (with the motor driver shield link). We were not able to achieve the final idea since we were short of available resources at the time of assembling. Motors which were available at this time were not suitable for this purpose.

We decided to constuct the prototype with manual controll of the motion. Redesign consisted of lever with shaft which runs small gear. The gear ratio is 1:10 (for the calculation we used gear generator).

Prototype

3D model of our prototype:

Final funcioning model of our solution is shown on the picture below.

Conclusion

In this article we described the process of analysing, designing and implementing programmable MusicBox. We started with specifying the solution parameters such as dimensions, number of notes and all requested components. Then we created 3D model in FreeCAD 0.19. We started with individual parts that were later assembled into the final model of our product. In order to do this we used Assembly 4 workbench.

During the course of our project we had to redesign the solution multiple times in order to fit the circumstances. Major redesign was needed when we acknowledged the fact that the solution will not be able to print out with the regular 3D printer. Also we had to improvise with the manual drive of a cylinder gear.

In the end we were able to deliver functioning prototype of our solution, which was able to play a simple song.

Links

- Link to EA Model

- Link to Manual (html); Manual (doc)

- Link to Technical documentation (html); Technical documentation (doc)

2023/2024

2023/2024